Bringing Down Emissions in Three Carbon-intensive Sectors

Three experts explain what it will take for some of the country’s biggest carbon-producing industries to reduce their emissions.

Taken together, transportation, electricity production, and indoor climate control account for well over half of the greenhouse gas emissions in the United States. In celebration of Climate Week NYC, Columbia Engineering asked three faculty members what it will take for these essential sectors to decrease their carbon emissions.

Bianca Howard

Bianca Howard, assistant professor of mechanical engineering, leads the Building Energy Research Laboratory, which develops modeling methods to understand the impacts of building decarbonization and electrification on energy systems, optimization approaches for developing building stock decarbonization pathways, and Al for real-time control of electrified heating and cooling systems.

What are some of the key obstacles to decarbonizing buildings in urban environments?

We have the technologies necessary to decarbonize New York City’s one million buildings, but it is difficult for a building owner to find a company that can design, develop and implement a plan from start to finish. The construction industry needs more people and companies with these skills.

Additionally, getting the most out of decarbonized buildings requires continuously adjusting how they operate as conditions change. Artificial intelligence can enable buildings and their operators to maintain energy-efficient buildings that interact with the grid as weather and energy conditions change. A lot of commercial offerings in this space provide intelligent analytics but not intelligent control.

What are the most promising solutions?

Many of the workers needed to decarbonize buildings can rely on on-the-job training. Positions that involve simulating the effects of building decarbonization require graduate training in building-energy modeling. Sponsored workforce development programs and advertising to young people about the magnitude of the opportunity in this space will attract the talent needed to fill these jobs.

Incorporating AI into building operations is difficult because each building has different building materials, layout, and occupant usage, as well as different heating, ventilation, and cooling systems and configurations. Research on incorporating reinforcement learning techniques for building control is in its early stages. Right now, the predictive machine-learning techniques are being deployed for complicated pieces of equipment, such as chillers.

Who is leading the way?

For workforce development, the New York State Energy Research and Development Program supports training and accelerator programs, such as the Clean Energy Apprentice Program, Clean Energy Internship Program, and On-the-Job Training Program. A company called BlocPower is leveraging innovative business models to integrate green workforce development in its efforts to retrofit all kinds of buildings.

No mature companies are incorporating AI control into buildings at scale, but several startups are trying to break through. This is an active area of research by researchers including myself, National Renewable Energy Laboratory, and Lawrence Berkeley National Laboratory.

Dan Esposito

Dan Esposito, associate professor of Chemical Engineering, leads the Solar Fuels Engineering Laboratory, which develops solar and electrochemical technologies that convert renewable and abundant solar energy into storable chemical fuels.

Why is it especially difficult to decarbonize heavy industry?

Many heavy industries rely on fuels rather than electricity for their most energy- and carbon-intensive processes. Fossil fuels have a high energy density, are easy to store, and are often used as reagents in chemical conversion processes. These advantages make it difficult for sectors such as chemical and cement manufacturing, metallurgy, and mining to quickly decarbonize using low- or zero-carbon electricity from solar and wind.

What technologies would make renewable a good choice in these settings?

Many researchers in my field are excited about the potential for electrochemical or photoelectrochemical technologies to reduce their carbon output more quickly. Those technologies can convert electricity or sunlight into renewable fuels or chemicals that more easily replace the fossil fuels and chemicals derived from fossil fuels that society relies on today.

One of the most commonly considered renewable fuels is hydrogen, which can be made from water through electrochemical reactions that are powered by renewable electricity — or directly by sunlight. Hydrogen is particularly versatile because it’s a chemical fuel that can be stored, burned to generate high-temperature heat, converted back into electricity using a fuel cell or turbine, or used directly as a reducing agent or reactant during the mass production of chemicals and materials.

Who is at the forefront right now?

One of the leading organizations in the area of sustainable chemical production isThe Center for Decarbonizing Chemical Manufacturing Using Sustainable Electrification (DC-MUSE), which includes a multidisciplinary group of over 20 academic research labs from 9 different universities — including NYU, Columbia Engineering, and The City College of New York.

Additionally, theColumbia Electrochemical Energy Centeris home to several research groups that are focused on developing materials and devices for efficiently producing zero-carbon renewable fuels and chemicals using electrochemistry. This includes my colleagues Dr. Jingguang Chen, Dr. Juliana Carneiro, and Dr. Alan West, in addition to myself.

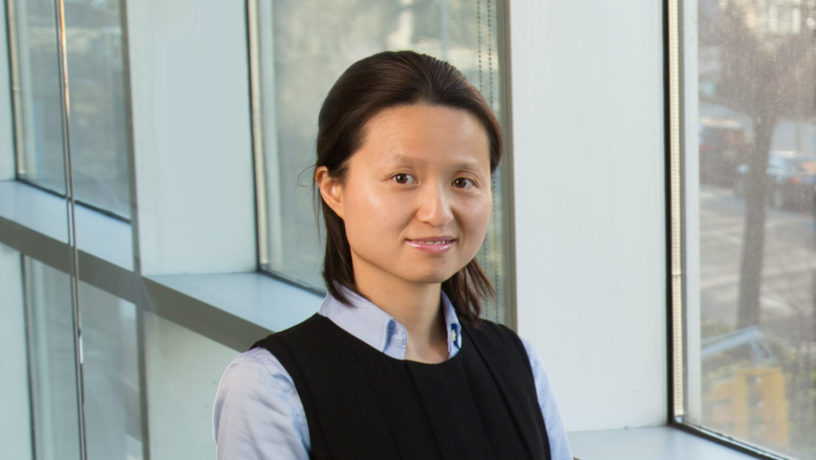

Sharon Di

Sharon Di, associate professor of civil engineering and engineering mechanics, leads the Data & Innovative Technology-driven Transportation Laboratory, which analyzes travel behavior and transportation systems to help transportation planners and managers maximize efficiency and sustainability.

What would a sustainable transportation system look like?

Sustainable transportation means increasing the use of mass transit and ride-sharing while decreasing the number of single-occupant vehicles on the road — and making sure those vehicles are electric.

The pandemic changed people’s habits from sharing rides/space to driving personal vehicles and not taking mass transit. If this “new normal” cannot be reversed, there will be a growing number of single-occupancy vehicles on roads and a constant decline in transit ridership.

What will it take to adjust course and change people’s habits?

It has to be a combination of more investment in transit infrastructure, congestion pricing, and incentives for sharing rides and carpooling. Even though the Biden administration aims to expand the EV charging station network, it could take decades to match the scale of petroleum gas stations. However, transportation electrification cannot solve traffic congestion. To be sustainable, we also need to encourage ridesharing and, most importantly, mass transit.

How are other countries approaching the problem of sustainable transportation?

China and Europe are leading the way in electric vehicle adoption and infrastructure. As these countries’ technologies dominate the market in this space, it will be increasingly difficult for the U.S. to catch up. Europe and Asia are also at the forefront of heavy investment in transit infrastructure. If the U.S. continues to focus on highways and personal transportation (even if those vehicles are electric), traffic congestion can never be solved.