New Technique Extends Next-Generation Lithium Metal Batteries

Columbia chemical engineers find that alkali metal additives can prevent lithium microstructure proliferation during battery use; discovery could optimize electrolyte design for stable lithium metal batteries and enable lightweight, low-cost, long-lasting energy storage for EVs, houses, and more

MEDIA CONTACT

Holly Evarts, Director of Strategic Communications and Media Relations

212-854-3206 (o), 347-453-7408 (c), [email protected]

JOURNAL

CELL REPORTS PHYSICAL SCIENCE

ABOUT THE STUDY

The study is titled “Leveraging Cation Identity to Engineer Solid Electrolyte Interphases for Rechargeable Lithium Metal Anodes.” Authors are: Richard May 1; Yumin Zhang 1; Steven R. Denny 1; Venkatasubramanian Viswanathan 2,3; Lauren E. Marbella 1

- 1 Department of Chemical Engineering, Columbia Engineering

- 2 Department of Materials Science and Engineering, Carnegie Mellon University

- 3 Department of Mechanical Engineering, Carnegie Mellon

The study was funded by the Alfred P. Sloan Foundation through a Scialog: Advanced Energy Storage Collaborative Innovation Award (2019-11419, LEM and VV). Richard May is supported by the U.S. Department of Defense through the National Defense Science & Engineering Graduate Fellowship Program.

The authors declare no competing interests.

The team used nuclear magnetic resonance imaging and computer simulations to better understand the reactivity and structure of molecules on the surface of lithium metal anodes that could lead to improved performance.

New York, NY—November 4, 2020—Electric vehicles (EVs) hold great promise for our energy-efficient, sustainable future but among their limitations is the lack of a long-lasting, high energy density battery that reduces the need to fuel up on long-haul trips. The same is true for houses during blackouts and power grid failures—small, efficient batteries able to power a home for more than one night without electricity don’t yet exist. Next-generation lithium batteries that offer lightweight, long-lasting, and low-cost energy storage could revolutionize the industry but there have been a host of challenges that have prevented successful commercialization.

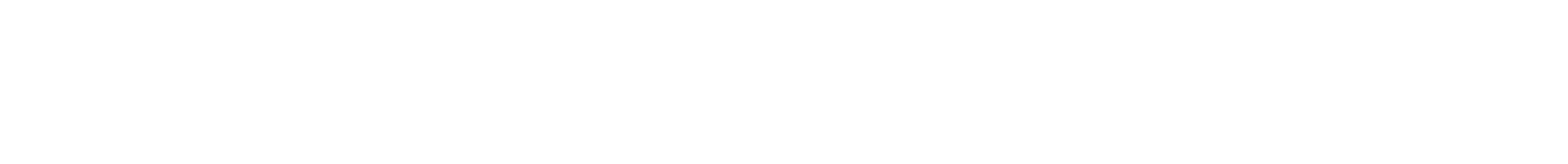

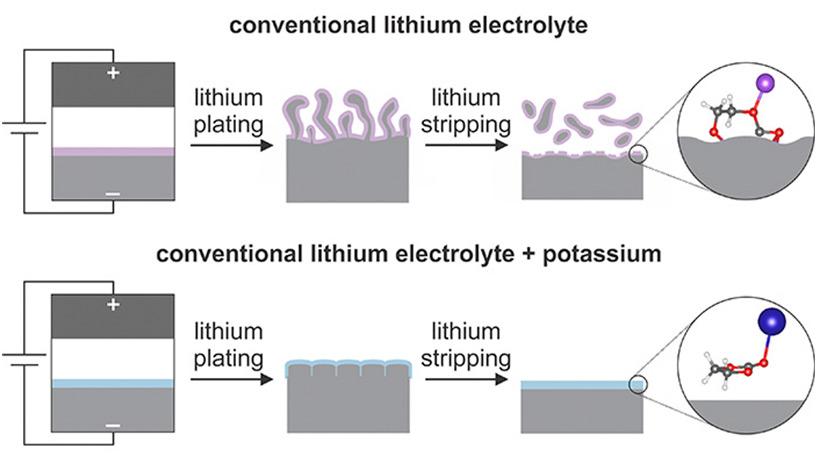

A major issue is that while rechargeable lithium metal anodes play a key role in how well this new wave of lithium batteries function, during battery operation they are highly susceptible to the growth of dendrites, microstructures that can lead to dangerous short-circuiting, catching on fire, and even exploding.

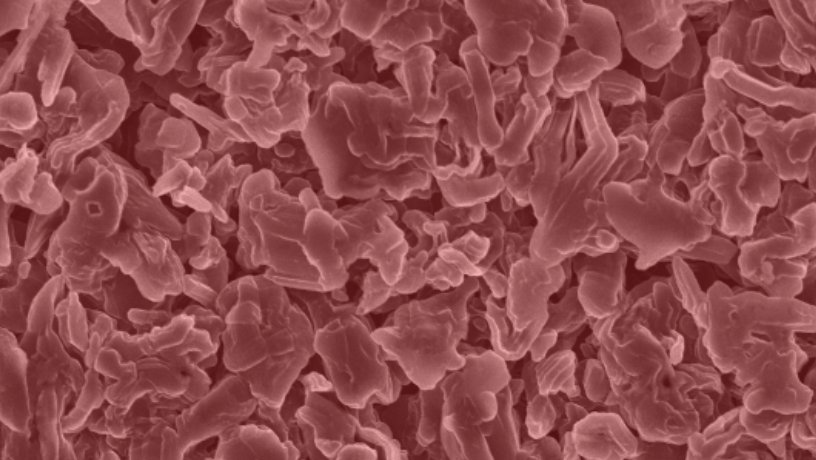

Researchers at Columbia Engineering report today that they have found that alkali metal additives, such as potassium ions, can prevent lithium microstructure proliferation during battery use. They used a combination of microscopy, nuclear magnetic resonance (similar to an MRI), and computational modeling to discover that adding small amounts of potassium salt to a conventional lithium battery electrolyte produces unique chemistry at the lithium/electrolyte interface. The study is published online today in Cell Reports Physical Science (and in the November 18th print edition).

Lithium metal batteries exhibit microstructural growth when cycled in conventional lithium battery electrolyte.

Addition of potassium ions to the electrolyte modulates degradation during battery operation, preventing the growth of microstructures and leading to safer, longer lasting batteries.

“Specifically, we found that potassium ions mitigate the formation of undesirable chemical compounds that deposit on the surface of lithium metal and prevent lithium ion transport during battery charging and discharging, ultimately limiting microstructural growth,” says the team’s PI Lauren Marbella, assistant professor of chemical engineering.

Her team’s discovery that alkali metal additives suppress the growth of non-conductive compounds on the surface of lithium metal differs from traditional electrolyte manipulation approaches, which have focused on depositing conductive polymers on the metal’s surface. The work is one of the first in-depth characterizations of the surface chemistry of lithium metal using NMR, and demonstrates the power of this technique to design new electrolytes for lithium metal. Marbella’s results were complemented with density functional theory (DFT) calculations performed by collaborators in the Viswanathan group in mechanical engineering at Carnegie Mellon University.

Columbia chemical engineers find that alkali metal additives can prevent lithium microstructure proliferation during battery use; discovery could optimize electrolyte design for stable lithium metal batteries and enable lightweight, low-cost, long-lasting energy storage for EVs, houses, and more.

“Commercial electrolytes are a cocktail of carefully selected molecules,” Marbella notes. “Using NMR and computer simulations, we can finally understand how these unique electrolyte formulations improve lithium metal battery performance at the molecular level. This insight ultimately gives researchers the tools they need to optimize electrolyte design and enable stable lithium metal batteries.”

The team is now testing alkali metal additives that stop the formation of deleterious surface layers in combination with more traditional additives that encourage the growth of conductive layers on lithium metal. They are also actively using NMR to directly measure the rate of lithium transport through this layer.

###

Columbia Engineering

Columbia Engineering, based in New York City, is one of the top engineering schools in the U.S. and one of the oldest in the nation. Also known as The Fu Foundation School of Engineering and Applied Science, the School expands knowledge and advances technology through the pioneering research of its more than 220 faculty, while educating undergraduate and graduate students in a collaborative environment to become leaders informed by a firm foundation in engineering. The School’s faculty are at the center of the University’s cross-disciplinary research, contributing to the Data Science Institute, Earth Institute, Zuckerman Mind Brain Behavior Institute, Precision Medicine Initiative, and the Columbia Nano Initiative. Guided by its strategic vision, “Columbia Engineering for Humanity,” the School aims to translate ideas into innovations that foster a sustainable, healthy, secure, connected, and creative humanity.